Sheet Metal Fabrication: Key Considerations for Buyers in 2025

The global demand for sheet metal fabrication continues to grow, especially from Chinese manufacturers known for their cost-effectiveness and advanced capabilities. Whether you're sourcing components for automotive, aerospace, or construction industries, understanding the nuances of this service is crucial for making informed decisions.

How to Find Reliable Sheet Metal Fabrication from China in 2025

Finding trustworthy sheet metal fabrication suppliers in China requires careful vetting. Start by verifying certifications like ISO 9001 and checking their production capacity. Platforms like Alibaba showcase numerous manufacturers with customer reviews and transaction histories. Look for suppliers with:

- Minimum 5 years of operational experience

- Clear communication channels (English-speaking staff)

- Quality control processes documented

- Flexible MOQ options

What Buyers Should Know Before Buying Sheet Metal Fabrication from China

Cultural and logistical differences can impact your procurement experience. Consider these factors:

- Lead times are typically 4-6 weeks including shipping

- Payment terms often require 30% deposit

- Material certifications may need explicit request

- Sample evaluation is strongly recommended

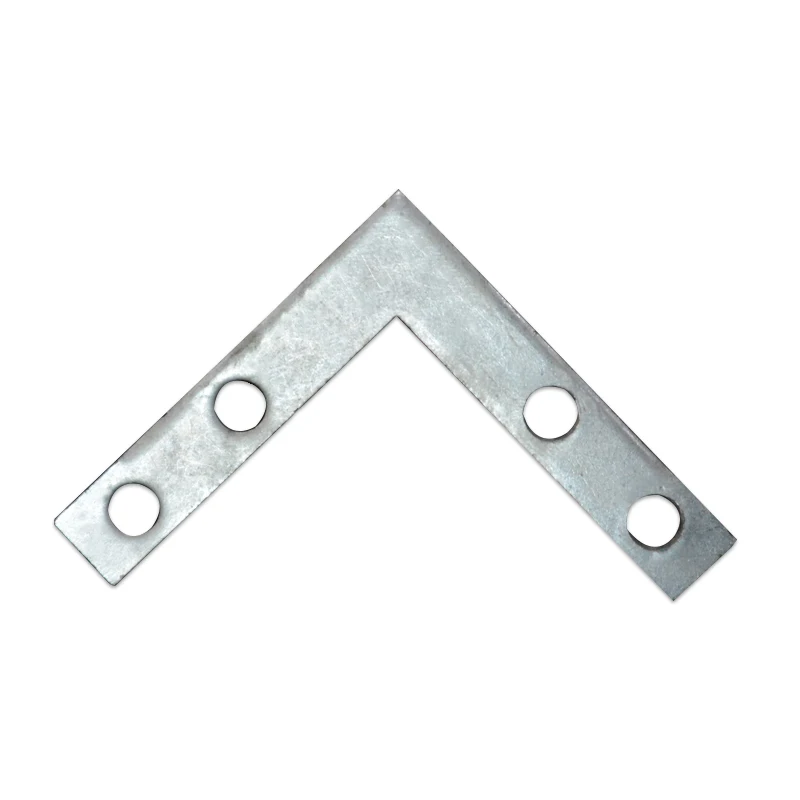

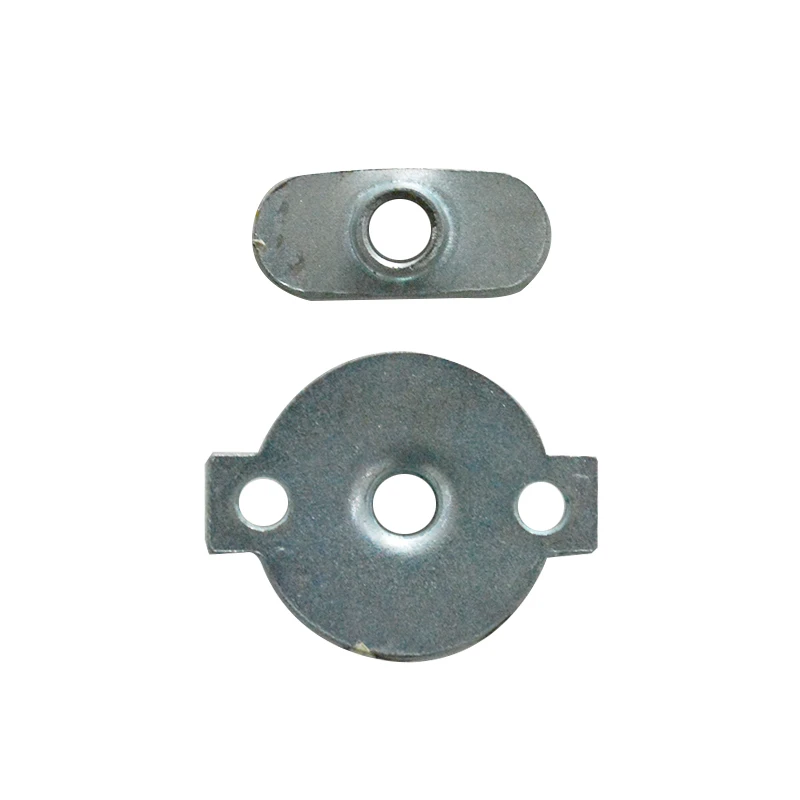

Types of Sheet Metal Fabrication

Different techniques serve various industrial needs:

Cutting Processes

Laser cutting offers precision for complex designs, while waterjet cutting handles thicker materials without heat distortion.

Forming Methods

Press braking creates precise angles, and roll forming produces consistent curved components.

Functions and features of Sheet Metal Fabrication

Modern sheet metal fabrication provides:

- Dimensional accuracy within ±0.1mm

- Material versatility (stainless steel, aluminum, copper)

- Surface treatment options (powder coating, anodizing)

- Prototype-to-mass production scalability

Scenarios of Sheet Metal Fabrication

These services support diverse applications:

Industrial Equipment

Machine enclosures and conveyor components require durable, precisely fabricated parts.

Architectural Elements

Custom facades and decorative features benefit from metal's versatility.

How to Choose Sheet Metal Fabrication

Selection criteria should include:

- Material compatibility with your application

- Required tolerances and finishes

- Supplier's experience with similar projects

- Cost-effectiveness at your volume

Sheet Metal Fabrication Q & A

Q: What's the typical turnaround time for custom orders?

A: Standard projects take 3-5 weeks, depending on complexity and order volume.

Q: How do Chinese suppliers maintain quality control?

A: Reputable factories implement QC checks at multiple stages and provide inspection reports.

Q: What file formats do manufacturers prefer for designs?

A: Most accept DXF, DWG, or STEP files, with PDF drawings for reference.

Q: Can I get both prototyping and mass production from one supplier?

A: Many Chinese fabricators offer both services, ensuring consistency from prototype to production.

Q: What are the advantages of sourcing from China?

A: Competitive pricing (typically 30-50% lower than Western suppliers), advanced equipment, and scalable capacity.