Fabric & Textile Raw Material: Sourcing, Types, and Buyer's Guide

The global demand for Fabric & Textile Raw Material continues to grow, with China remaining a top supplier. Whether you're a manufacturer, designer, or retailer, understanding how to source reliable materials is crucial. This guide covers everything from types and features to practical buying tips.

How to Find Reliable Fabric & Textile Raw Material from China in 2025

China dominates the textile raw material market, offering competitive pricing and diverse options. To find trustworthy suppliers:

- Verify certifications like OEKO-TEX or GOTS

- Request physical samples before bulk orders

- Check supplier transaction history on B2B platforms

- Consider attending trade shows like Intertextile Shanghai

Top sourcing platforms include Alibaba (for smaller orders) and Made-in-China (for bulk purchases). Always negotiate MOQs and lead times directly.

What Buyers Should Know Before Buying Fabric & Textile Raw Material from China

Key considerations include:

- Import duties and shipping costs (typically 10-25% of product value)

- Minimum Order Quantities (MOQs) ranging from 100-10,000 meters

- Standard lead times of 30-60 days for custom orders

- Payment terms (30% deposit is common)

Case Study: A UK fashion brand reduced material costs by 40% by switching to a verified Guangdong supplier while maintaining quality standards.

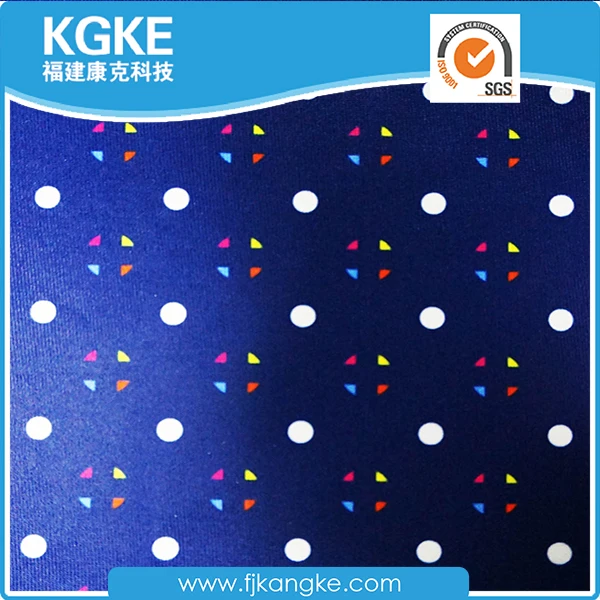

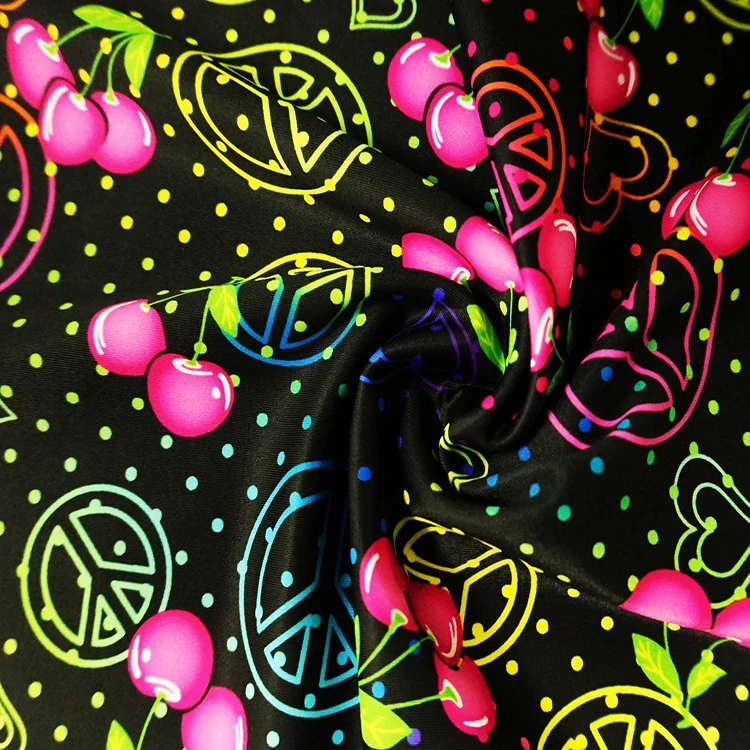

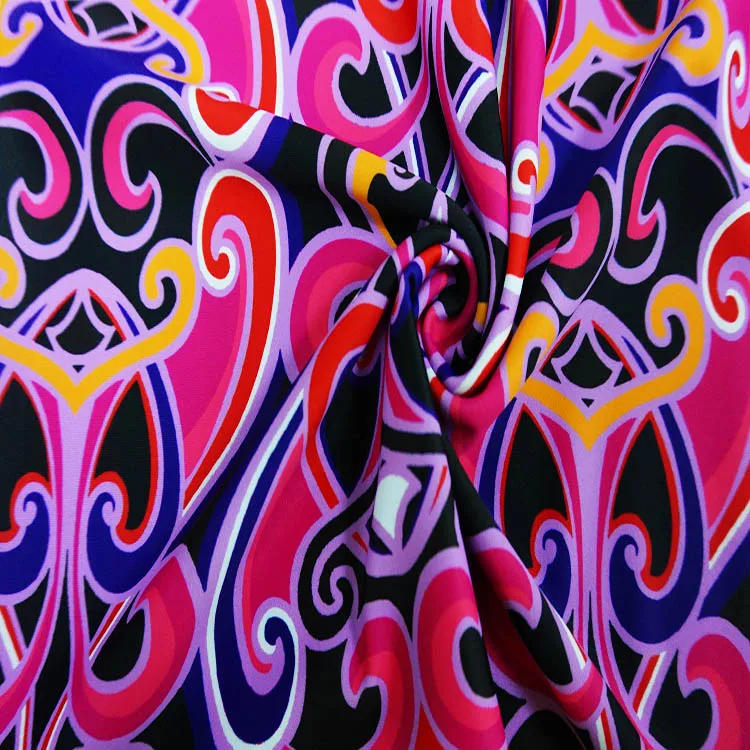

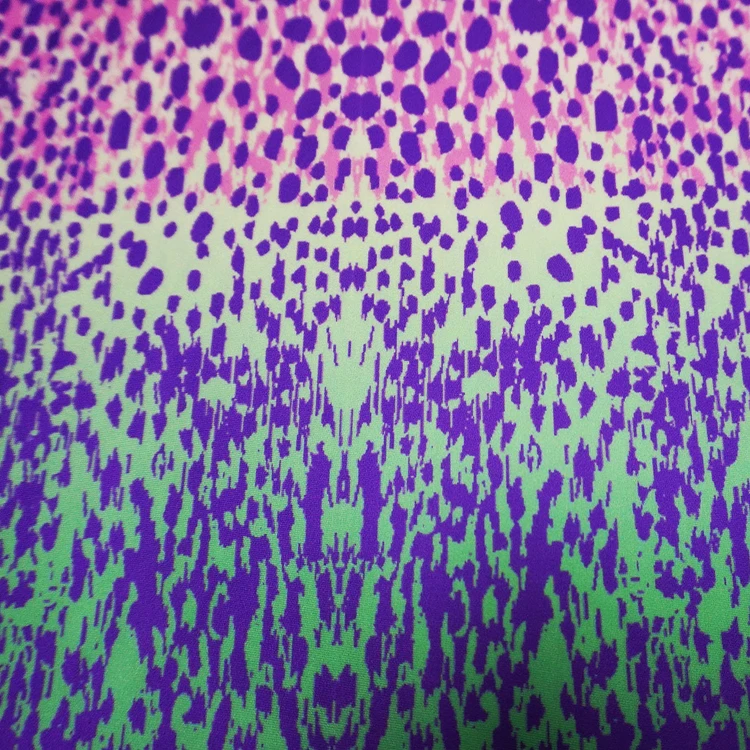

Types of Fabric & Textile Raw Material

Major categories include:

Natural Fibers

- Cotton (most versatile, 40% of global textile production)

- Wool (premium thermal properties)

- Silk (luxury applications)

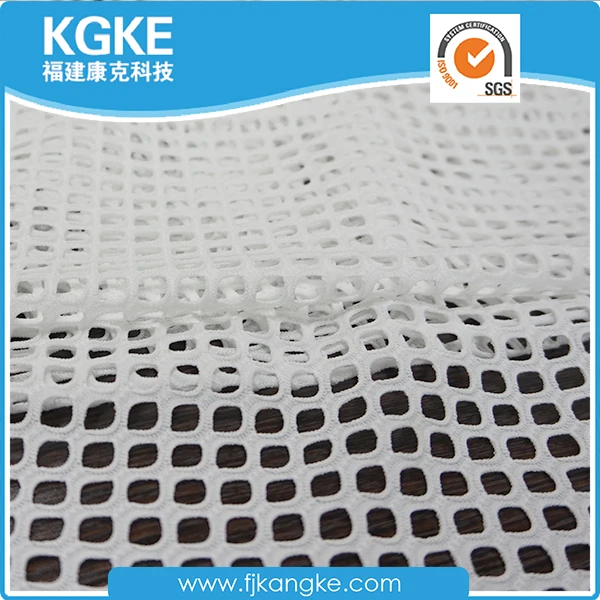

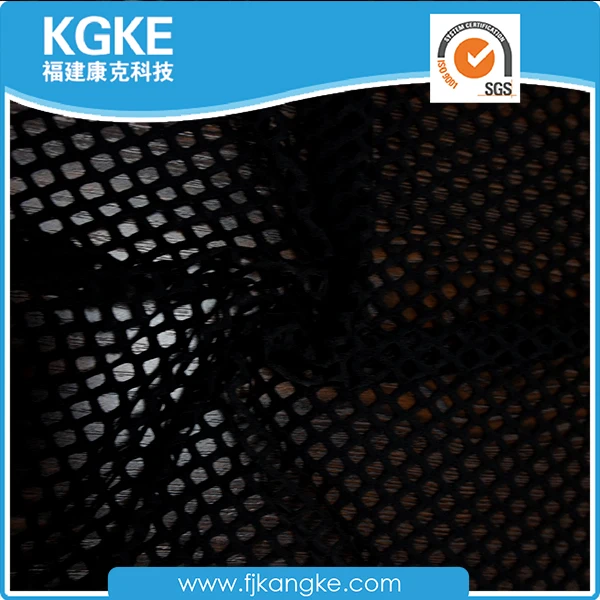

Synthetic Fibers

- Polyester (65% of synthetic fiber market)

- Nylon (high durability)

- Spandex (for stretch fabrics)

Functions and features of Fabric & Textile Raw Material

Key functional attributes:

| Material | Key Feature | Best For |

|---|---|---|

| Organic Cotton | Breathability (air permeability 50-100 cfm) | Babywear, activewear |

| Recycled Polyester | Moisture-wicking (dries 2x faster than cotton) | Sportswear |

Scenarios of Fabric & Textile Raw Material

Application-specific considerations:

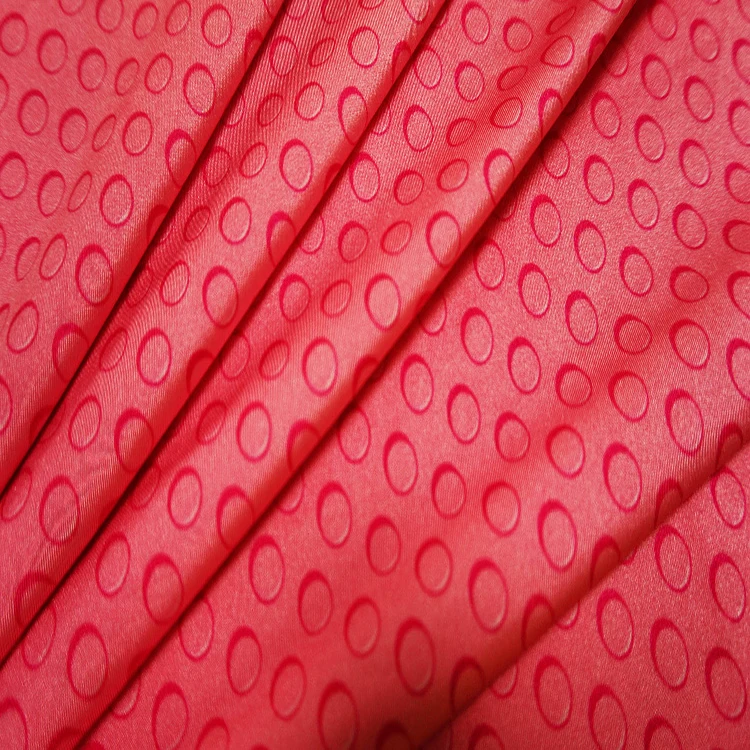

- Apparel: Focus on drape, comfort, and care requirements

- Home Textiles: Prioritize durability and colorfastness

- Technical Textiles: Require specialized properties like flame resistance

How to Choose Fabric & Textile Raw Material

Selection criteria:

- Define end-use requirements (stretch, weight, etc.)

- Test for performance characteristics

- Compare cost vs. quality tradeoffs

- Evaluate sustainability credentials

Pro Tip: Request a Fabric & Textile Raw Material swatch card from suppliers for accurate color and texture assessment.

Fabric & Textile Raw Material Q & A

Q: What's the difference between greige goods and finished fabrics?

A: Greige goods are unprocessed textiles straight from the loom, while finished fabrics have undergone treatments like dyeing or coating.

Q: How do I verify fabric composition claims?

A: Request third-party test reports or conduct burn tests (cotton smells like burning paper, synthetics melt).

Q: What's the typical MOQ from Chinese mills?

A: Ranges from 1,000-10,000 meters depending on material complexity.

Q: Are Chinese textile raw materials quality comparable to European?

A: Top-tier Chinese mills now match European quality at 20-30% lower cost, but rigorous vetting is essential.

Q: How to ensure color consistency across batches?

A: Request lab dips and approve a color standard before production begins.