EPDM Rubber: Sourcing, Types, and Applications for Buyers

EPDM (Ethylene Propylene Diene Monomer) is a versatile synthetic rubber widely used in automotive, construction, and industrial applications. Its excellent weather resistance, durability, and flexibility make it a preferred material for seals, gaskets, roofing membranes, and more. This article provides practical insights for buyers looking to source high-quality EPDM from reliable suppliers.

How to Find Reliable EPDM from China in 2025

China remains a leading producer of EPDM, offering competitive pricing and diverse formulations. To find trustworthy suppliers:

- Verify certifications: Look for ISO 9001, REACH, or RoHS compliance.

- Check production capacity: Ensure the supplier can meet your volume needs.

- Request samples: Test material properties before bulk orders.

- Read reviews: Platforms like Alibaba provide buyer feedback on manufacturers.

What Buyers Should Know Before Buying EPDM from China

Key considerations include:

- Mooney viscosity: Affects processing ease (typically 40-80 for most applications).

- Diene content: Higher diene improves crosslinking but may reduce weather resistance.

- Lead times: Factor in 30-60 days for production and shipping.

- Customization: Many Chinese suppliers offer compound tailoring for specific needs.

Types of EPDM

Three primary classifications exist:

- Sulfur-cured: Most common, excellent for general-purpose applications

- Peroxide-cured: Superior heat resistance (up to 150°C continuous)

- Oil-extended: Contains process oils for improved workability

Functions and features of EPDM

Key advantages include:

- Temperature range: -50°C to +150°C

- Excellent ozone and UV resistance

- Low compression set (typically <25%)

- Good electrical insulation properties

- Resistant to polar fluids and mild chemicals

Scenarios of EPDM

Common applications:

| Industry | Application |

|---|---|

| Automotive | Weatherstripping, hoses, seals |

| Construction | Roofing membranes, expansion joints |

| Industrial | Gaskets, conveyor belts, vibration dampers |

| Consumer | Appliance seals, sporting goods |

How to Choose EPDM

Selection factors:

- Identify environmental exposure (UV, chemicals, temperature)

- Determine mechanical requirements (tensile strength, elongation)

- Consider processing method (extrusion, molding, calendaring)

- Evaluate cost vs. performance needs

EPDM Q & A

Q: How does EPDM compare to natural rubber?

A: EPDM offers better weather resistance but lower tensile strength than natural rubber.

Q: What's the typical lifespan of EPDM roofing?

A: Properly installed EPDM roofs last 30-50 years, outperforming most alternatives.

Q: Can EPDM withstand fuel exposure?

A: No, it swells in petroleum-based fluids. Use FKM for fuel resistance.

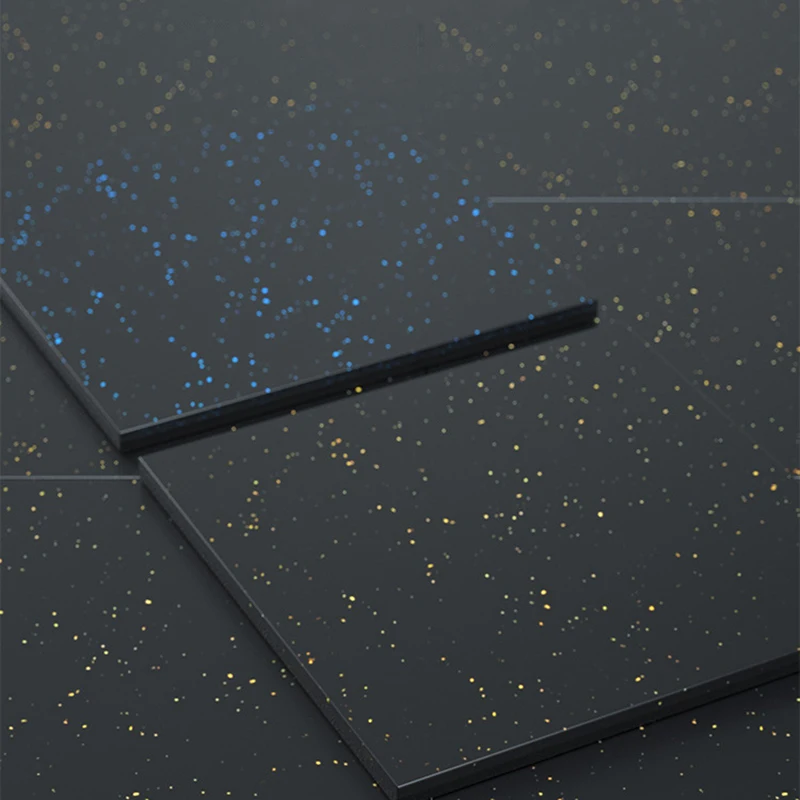

Q: What colors does EPDM come in?

A: Black is standard, but custom colors (white, gray) are available with additives.

Q: How do I test EPDM quality?

A: Request ASTM D2000 test reports for key properties like hardness and elongation.

-804.png_300x300.webp)